On-Site Machining

Doosan Škoda Power has been using On-Site Machining technology during overhauls, modernization and retrofits when machining large turbine components directly in power plants successfully for several years now.

On-Site Machining

The economic benefits of machining of large parts directly in power plants are essentially that it is not necessary to arduously disassemble large and heavy components, transport them to the manufacturing facility and, after the necessary machining works, transport them back to the power plant and then re-install them again to the original position and re-connect parts, such as the piping, field instrumentation, insulation and so on.

Among the many advantages of On-Site Machining technology is time and cost saving.

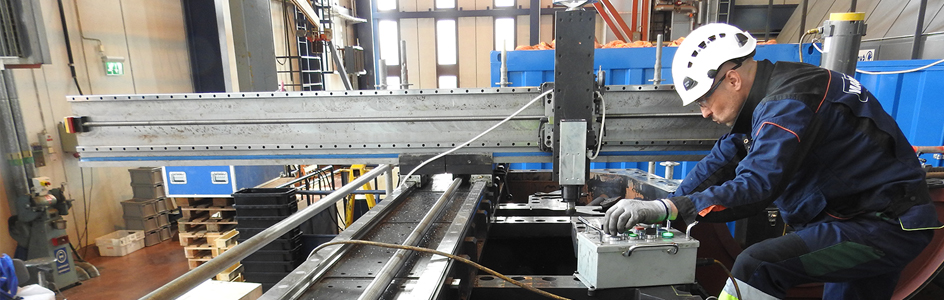

While applying On-Site Machining technology, Doosan Škoda Power uses a wide range of mobile machining devices.