Engineering and Technical advisory

Doosan Škoda Power offers complex engineering solutions to maximize the efficiency of turbomachinery equipment and extend its operational lifetime. High-end tools and more than 100 years of experience allow us to deliver high quality services and meet your needs.

High-Speed and Field balancing

Methodology and technique for balancing and centrifuging rotors

Usual test procedure:

- A rotor test, in which the critical speed position and the balancing state are detected

- Pre-balancing, if it is necessary for safe execution of the spin test

- Centrifugation, which is carried out at the revolutions specified by the customer for a specified period of time

- Final precision balance

Other information about the test procedure:

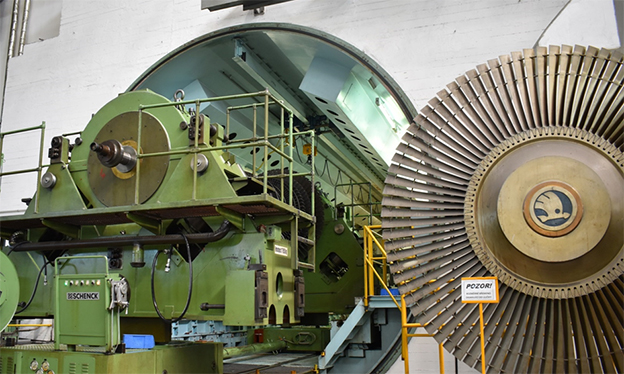

Balancing is performed in several balancing planes and at several levels of balancing speed using the influence coefficient method. The measured vibration vectors in each test are gathered and evaluated using the CABFLEX ++ program in the SCHENCK control computer. The computer optimizes the distribution of balancing weights, so that the vibration is minimal in the entire counterbalanced range.

The device is also equipped with SCHENCK VIBROCONTROL 4000 systems, which enable non-contact vibration measuring, including RUN-OUT on different parts of the rotor.

With the CABFLEX ++ program in the SCHENCK computer, the vibration data can be collected and then printed in the form of tables or graphs (e.g. BODE- or NYQIST – diagram).

Field balancing

Our company is able to provide rotor balancing in the field when the machine is only partially open. Balancing can only be done on rotor clutches after the bearing pedestals have been opened. If the design of the turbine allows for insertion of the weights closer to the rotor’s centre, it is possible to install the weights there, and the balancing becomes more efficient.