Engineering and Technical advisory

Doosan Škoda Power offers complex engineering solutions to maximize the efficiency of turbomachinery equipment and extend its operational lifetime. High-end tools and more than 100 years of experience allow us to deliver high quality services and meet your needs.

Residual Life Assessment

Residual Life of a material is the time during which it retains its fitness-for-service characteristics. Extensive and expansive inspection programmes have to be undertaken, alongside routine operations, in order to monitor the extent of in-service deteriorations. Residual Life Assessment (RLA) studies are conducted on power plant components and their machineries which are subjected to fatigue and/or creep loading conditions.

Metallurgical Assessment

- Assessment of the service life of the material – evaluation of the microstructure, creep assessment, stress, etc.

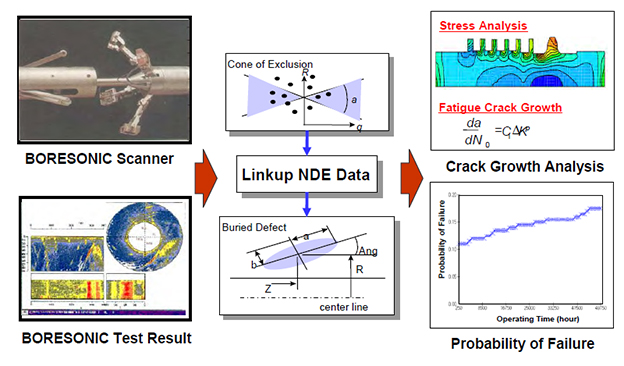

Life Assessment

- Assessment of the remaining life of the turbine – Boresonic, Linkup Analysis, Stress Analysis, Crack Growth Analysis