Field and Site Service

Our field service teams are ready to operate at your site worldwide. Turbine engineers and experts can provide you with highly professional assistance, troubleshooting or any service you may need.

Endoscope Inspection

We are primarily focused on inspection of turbines, piping and heat exchangers; however, it is possible to arrange a inspection of other machines and devices. We have a special Kummert SmartCam camera system, which can reach up to 60 meters, for checking the cleanliness of large pipes over DN150.

Conditions for endoscope inspection:

- Access to the place of the inspection

- The inspected machine is cooled down below 60 – 80°C (depending on the machine)

The endoscope inspection is carried out from two main reasons:

1. Preventive endoscope inspection

Regular preventive inspection focused on the turbine’s flow section condition is standard part of the maintenance process and helps to the turbine operator to plan general overhauls and its scope.

Evaluation of inspection findings is done based on equipment producer criteria or by comparison of damage progress based on data from previous inspections.

Inspection main focus:

- Intact conservation (checked before put into operation)

- The quality of the welding work done on the piping

- The cleanliness of the piping

- Mechanical damage of the blading and other parts

- The presence of inappropriate objects in the flow sections

- Residue on the blading

- Corrosion of the blading and other parts

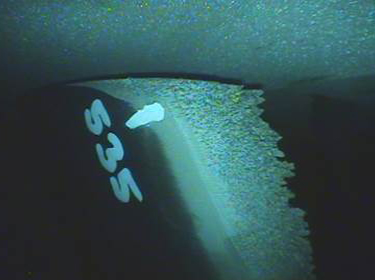

- Erosion development caused by wet steam

- The condition of the sealing in steam armature seats

Steam turbine blade erosion inspection

Steam turbine stages inspection

2. Emergency endoscope inspection

In emergency cases an endoscope check helps to the fast identification of the failure. Than the reparation plan can be quickly defined.

Inspection main focus:

- Mechanical condition of the blades – damage, breaks

- The presence of inappropriate objects in the steam flow path

- Other emergency causes