Engineering and Technical advisory

Doosan Škoda Power offers complex engineering solutions to maximize the efficiency of turbomachinery equipment and extend its operational lifetime. High-end tools and more than 100 years of experience allow us to deliver high quality services and meet your needs.

Diagnostics

Diagnostics of your Steam Turbine gives you detailed information on when preventive maintenance is required. Our extensive experience in diagnostics includes:

– Vibration measurement

– RAMS (Rub Advanced Monitoring System)

– Blade dynamics, Blade Monitoring

– Vibration measurement

– RAMS (Rub Advanced Monitoring System)

– Blade dynamics, Blade Monitoring

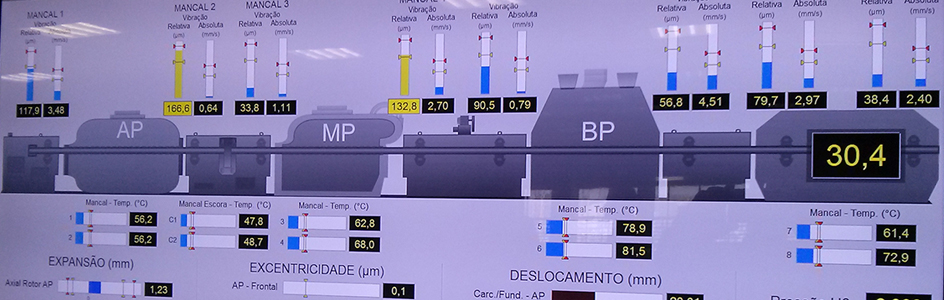

Vibration measurement

Doosan Škoda Power provide vibro-measurement and vibro-diagnostics of rotor systems and rotating parts with subsequent evaluation and recommendations. It is also possible to evaluate the data collected and sent by the customer.

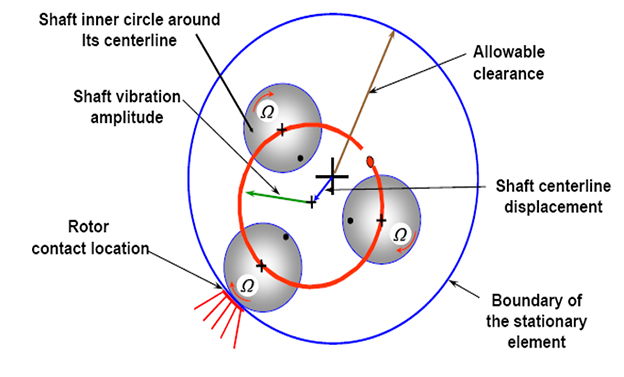

RAMS (Rub Advanced Monitoring System):

- Can detect and localize a rub in the turbine

- Axial and circumferential localization of contact

- Uses the existing sensors of the turbine

- Online detection of rotor/stator contact

- High accuracy (24-bit resolution)

- Evaluation of the contact type (partial and full contact) and rub intensity

- Visualization of diagnostic features, orbits, full cumulative spectra, etc.

- Triggering and disc file streaming for potential detailed offline signal analysis and evaluation

- Monitoring of all turbine states (run-up and run-down, various load levels, turning gear operation, etc.)

Blade dynamics, Blade Monitoring System (BMS)

BMS enables the prediction of cracks in the blading, based on:

- Blade lean – BMS detects if a cracked blade is leaning

- Blade frequency shift – BMS evaluates a blade frequency shift by detection of blade detuning caused by crack propagation

- BMS can prevent a blade failure with all its negative consequences, such as financial costs and/or the commitment to supply power

- BMS helps the turbine operator avoid modes that reduce the turbine’s service life

- BMS automatically generates reports on a daily, weekly or monthly basis, which summarize the blades’ vibration history and their condition

Doosan Škoda Power provide full support of BMS, including:

- Engineering

- accommodation sensors and determining the quantity

- choosing the most suitable sensors

- tubing and wiring, etc.

- Manufacturing & Installation

- on-site machining

- sensor and wiring installation

- Data acquisition and evaluation

- Support & Maintenance