3D Scanning and Reverse Engineering

Since 2011, Reverse Engineering in Doosan Škoda Power has undergone an enormous development and was integrated into the standard methods used both in developmental and production processes, and primarily for Non-OEM retrofits and modernization project execution.

Do you want to reconstruct a small object in size or do you want to gather 3D geospatial data from a hall or a building? We are most qualified to offer you solutions tailored to your needs.

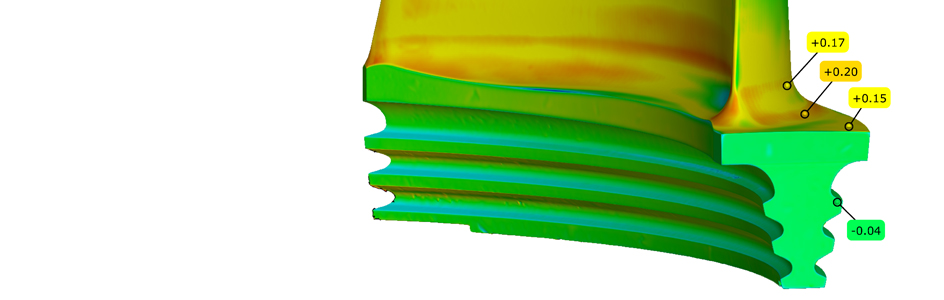

Geometrical diagnostics

3D scanners do not necessarily serve only for obtaining data for reverse engineering but are very powerful tools for a quick determination of the current state of the components. For example the dimensions, deformation, actual deviation, tolerance verification, volume or surface measurements are just a part of our portfolio.

Geometrical diagnostics application:

- CEA Analysis (FEA / CFD)

- Troubleshooting

- Quality Assurance

- Gear Inspections

- Non-contact inspection

- Alignment

- Dimensional analysis

- Inspection of large parts

- Machine calibration

Geometry innovation

Blade profile improvement

Volume analysis

Material volume loss due to cavitation

Geometrical analysis

Parting plane actual deviations

Gear Inspection

Journal bearing dimensional analysis